Adding an appropriate amount of animal and vegetable oil to feed not only enhances the energy content of the feed but also improves the appearance and quality of pellet feed. The process of incorporating fat can be done either before or after granulation. When added before granulation, the typical amount should not exceed 3% of the total production. Exceeding this limit may lead to issues such as loose pellets and is unsuitable for extruded feed. This method requires less advanced equipment. On the other hand, applying oil after granulation—commonly known as grease spraying—can allow up to 8% oil addition. This approach effectively addresses concerns about oil affecting pellet hardness, significantly boosting productivity and making it more suitable for producing expanded feed. However, this method demands higher-quality equipment and more precise operational control.

**1. Basic Structure, Requirements, and Working Principle of Grease Spraying**

There are two main types of grease spraying methods: one involves spraying during particle extrusion, while the other occurs after classification. Despite the differences in application timing, both require similar components in terms of oil supply and electronic control systems.

A grease spraying system typically includes a self-regulating oil tank, coarse and fine filters, control valves, compressed air, high-pressure steam, and a controller. The oil tank is equipped with a level sensor, temperature controller, heating elements, and an agitator. These components work together to heat the oil to between 60–80°C, reducing its viscosity and improving flowability for better absorption. Coarse and fine filters prevent impurities from clogging the system, ensuring smooth operation of valves, gauges, and nozzles. Compressed air or steam is used to atomize the oil into a fine mist, enabling even distribution over the pellets. The spray controller is a critical component that automatically adjusts and displays the oil flow rate, featuring alarms for oil shortages and flow deviations. Additionally, the oil piping must be heated and insulated to prevent solidification and maintain consistent performance.

**2. Basic Requirements**

- All pipeline components must operate reliably without oil or steam leakage.

- A minimum working pressure of 0.2–0.5 MPa must be maintained in both oil and steam lines.

- The pipeline should include coarse and fine filters to prevent nozzle clogging and ensure accurate spray measurement.

- The oil tank and injection system must have heating devices, and the piping should be insulated to prevent oil solidification.

- The system should have a high degree of automation, allowing the grease amount to adjust according to the feed output.

- The spray rate should be customizable based on user needs.

- The sprayed oil mist should evenly cover the material path, minimizing waste and ensuring uniform coating.

**3. Working Principle**

When grease enters the oil tank through a coarse filter, it is automatically heated to 60–80°C using steam heating tubes. The pipeline is also preheated to a set temperature, and the tank is equipped with a stirrer to ensure even heating and accurate temperature control. Once the oil path is confirmed clear, the spraying process begins. The grease is pumped through a speed control pump, check valve, and fine filter, then sprayed onto the pellet surface under compressed air pressure. The actual spray volume is measured by an elliptical gear flow transmitter and sent to a programmable controller, which adjusts the pump speed accordingly to achieve the desired spray amount. This ensures precise and efficient grease application.

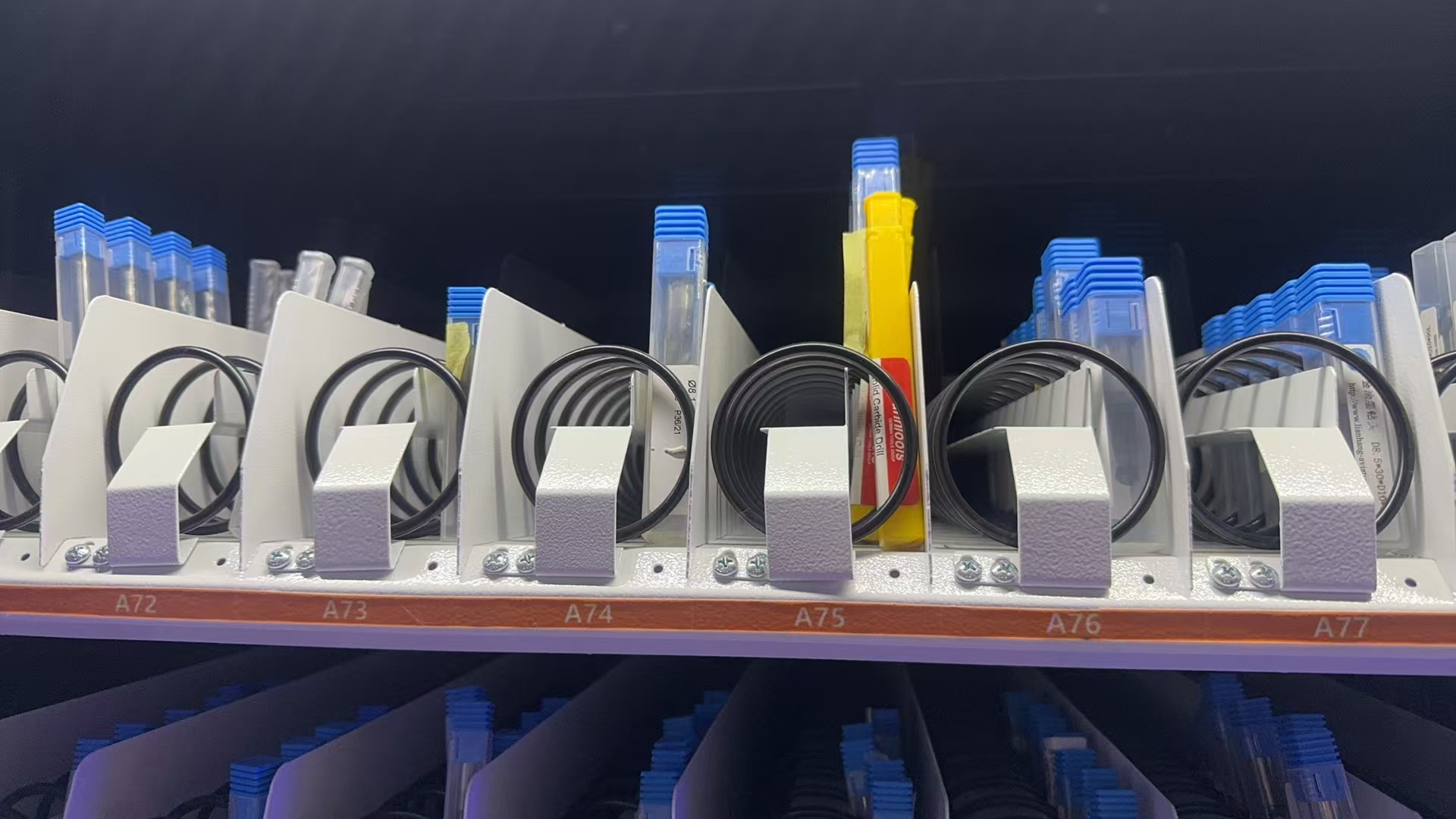

Dual Access Smart Coil & Grid Cabinet

Two dispensing ports for faster, smarter tool distribution

This cabinet combines spring coils and grid compartments with dual access windows, allowing two users to pick up items at the same time. It improves efficiency in busy workshops while maintaining full control over access and inventory.

Each side can be configured independently, supporting different item types such as boxed cutting tools, inserts, gloves, or small parts. With smart access control (RFID, face, code), real-time inventory tracking, and modular design, it’s ideal for factories with high tool turnover.

Applications:

CNC workshops, toolrooms, consumable management in production lines.

Highlights:

Dual user access, mixed storage modes, fast tool dispensing, customizable layout, real-time tracking.

Intelligent Workside Tool Cabinet,Intelligent Tool Handle Management Cabinet,Intelligent Labor Protection Equipment Management Cabinet,Intelligent Tool Management Cabinet

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com